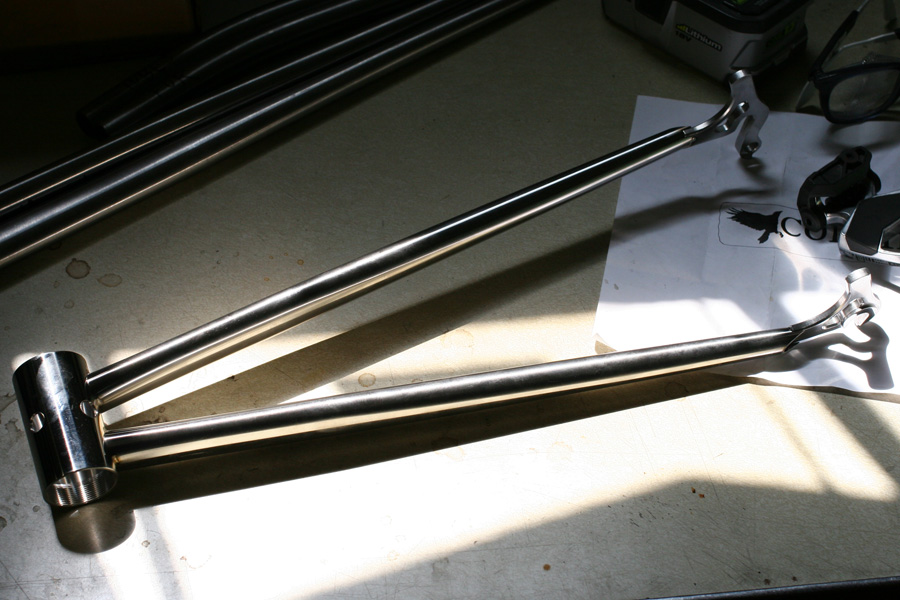

The Columbus XCr chainstay sub assembly is completed. The sub assembly includes bottom bracket, chainstays and dropouts.

The Columbus XCr chainstay sub assembly is completed. The sub assembly includes bottom bracket, chainstays and dropouts.

The pieces were mitered, slotted, cleaned, argon purged then tack welded together in our sub assembly jig.

The XCr stainless steel tubing cut and tacked together well. Below you can see the small metal tack welds holding the sub assembly together as well as the purge holes that allow the argon to flow (eventually) through the frame as it is welded.

The XCr stainless steel tubing cut and tacked together well. Below you can see the small metal tack welds holding the sub assembly together as well as the purge holes that allow the argon to flow (eventually) through the frame as it is welded.

All welding (and tacking) is done with a special alloy wire. The wire is actually the same alloy as the XCr tubing itself and is provided with the tubeset by Columbus .

All welding (and tacking) is done with a special alloy wire. The wire is actually the same alloy as the XCr tubing itself and is provided with the tubeset by Columbus .

These are actually not the dropouts supplied by Columbus, they are the same “Indy Fab” 17-4 dropouts we use on our 953 SSR’s. I talked with our metallurgist to find out about alloy compatibility and and got the go-ahead.

These are actually not the dropouts supplied by Columbus, they are the same “Indy Fab” 17-4 dropouts we use on our 953 SSR’s. I talked with our metallurgist to find out about alloy compatibility and and got the go-ahead.

I polished (sanded to 1500 grit) the inside and outside faces of the dropouts before tacking them together. The final polish with cloth and rouge will take place after the frame is completed.

I polished (sanded to 1500 grit) the inside and outside faces of the dropouts before tacking them together. The final polish with cloth and rouge will take place after the frame is completed.

Look for more installments of The Stainless Report coming soon.

oh man that thing is going to be so pretty. i can’t wait to see it finished.

and the photography is pretty …well pretty really!

Stop messing around and finish my frame! 😉

You wish! That baby is MINE! 😉 I’m building it on off hours so as not to disrupt production so I only work on it a little bit every couple of days…. patience, patience (at least that’s what I keep telling myself), Tyler.

Anxiously awaiting my ordered SSR!

This XCr tubing is very attractive. Cinelli offers it. But how does it compare to 953? Do you think that the 953’s being annealed compared to the XCr’s seamless makes any big difference in durability? Sure is beautiful tubing.