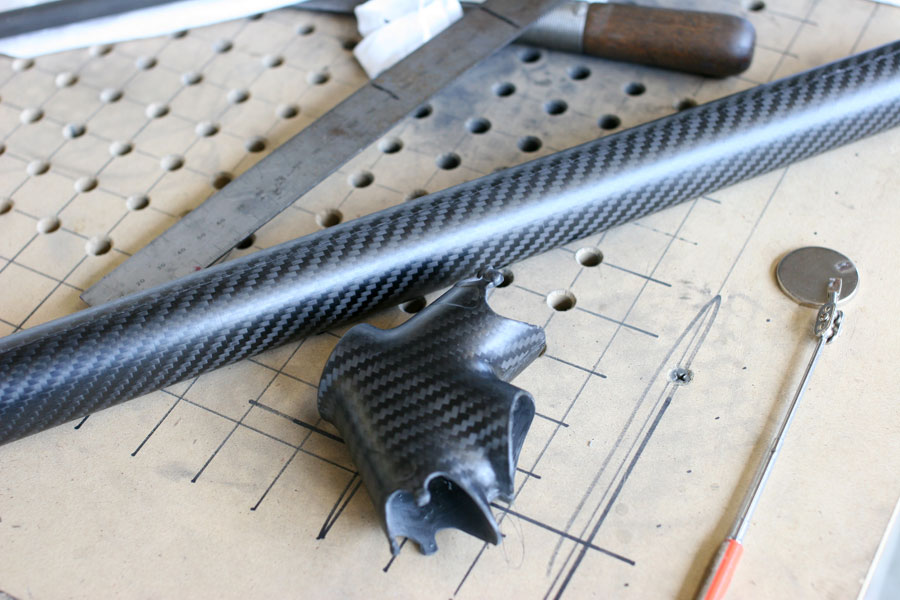

Carbon fiber Corvid lugs are being cleaned up on the downdraft table above. Each lug is individually prepped for each custom frame.

Carbon fiber Corvid lugs are being cleaned up on the downdraft table above. Each lug is individually prepped for each custom frame. This is our new do-all carbon fiber cutting machine… dubbed: “The Horizontal Plow” by Sputnik Tool. It has various modular parts that plug in to miter each tube.

This is our new do-all carbon fiber cutting machine… dubbed: “The Horizontal Plow” by Sputnik Tool. It has various modular parts that plug in to miter each tube. Below is a close up of one of the diamond tipped hole saws that we use for plowing through the carbon fiber tubing.

Below is a close up of one of the diamond tipped hole saws that we use for plowing through the carbon fiber tubing. Each lug is made for an individual build. Inside the lugs you can see the name of the end customer that it is intended for.

Each lug is made for an individual build. Inside the lugs you can see the name of the end customer that it is intended for. We are building a couple here… one for Spinelli and one for Wolfson.

We are building a couple here… one for Spinelli and one for Wolfson. Until we get the dust collector hooked up Jamie miters the tubes (below) and sucks the dust away with a shop vac outfitted with a fine particulates dust filter inside.

Until we get the dust collector hooked up Jamie miters the tubes (below) and sucks the dust away with a shop vac outfitted with a fine particulates dust filter inside.

The tubes are fit up in the jig before the lugs are put on. This ensures that straight alignment, exact geometry and maximum bond surface….

The tubes are fit up in the jig before the lugs are put on. This ensures that straight alignment, exact geometry and maximum bond surface…. The two piece dropouts are welded together in our welding department and are part of a sub assembly that ensures a good wheel check.

The two piece dropouts are welded together in our welding department and are part of a sub assembly that ensures a good wheel check. Before bonding the frame together it is dry fit and inspected (more like drooled on) by Sparky (Wolfson)… this is the bike from a couple of posts ago… Radly.

Before bonding the frame together it is dry fit and inspected (more like drooled on) by Sparky (Wolfson)… this is the bike from a couple of posts ago… Radly.

(603) 292-5673 sales@ifbikes.com 271 Western Ave Lynn, MA 01904 Monday – Friday: 10AM – 6 PM Shop Visits By Appointment Only

great pics…. very informative.