Now we saunter over to the finishing department where the titanium cross frame we have been working on for Signature Cycles gets all of its final treatments that will make it into a rideable bike. For example: the headtube gets its final ream and face.

Now we saunter over to the finishing department where the titanium cross frame we have been working on for Signature Cycles gets all of its final treatments that will make it into a rideable bike. For example: the headtube gets its final ream and face.

The seat tube is reamed out to eliminate the weld distortion and give it the proper inner diameter to accept the e-glass insert that will get bonded in.

The seat tube is reamed out to eliminate the weld distortion and give it the proper inner diameter to accept the e-glass insert that will get bonded in.

The frame will go another round on the alignment table to make sure everything is perfect.

The frame will go another round on the alignment table to make sure everything is perfect. Then it will get the “wheel check” checked again to make sure that the wheel sits perfectly on the center line of the frame.

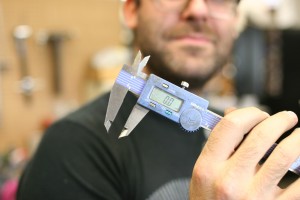

Then it will get the “wheel check” checked again to make sure that the wheel sits perfectly on the center line of the frame. Each side of the tool is measured and if there is any variance then the inside of the dropout is filed until the tool sits perfectly centered.

Each side of the tool is measured and if there is any variance then the inside of the dropout is filed until the tool sits perfectly centered.

After finishing, the frame is sent off to the shotpeeners. Upon its return it will go into the paint department. This frame is about to receive a most manly paint job……. stay tuned….

After finishing, the frame is sent off to the shotpeeners. Upon its return it will go into the paint department. This frame is about to receive a most manly paint job……. stay tuned….

(603) 292-5673 sales@ifbikes.com 271 Western Ave Lynn, MA 01904 Monday – Friday: 10AM – 6 PM Shop Visits By Appointment Only

These Bikes are true works of art. I have started saving for my own. Hopefully it won’t take to long. Kepp up the brilliant work…

I wish my old 1920s South Bend lathe still was true enough to face headtubes. I have the same lathe in the corner of the shop collecting dust, the 1/4 inch of run out doesn’t do it anymore.

great work man! hey why dont u use Laser welding i m sure it can make ur work easier. BTW nice tattoos 🙂